The Most Influential People In The Low Volume Manufacturing Singapore

When it comes to low volume manufacturing singapore, it is very common for there to be misconceptions about the cost of bringing a new product to market. This mistake can be devastating as costs can quickly spiral out of control during prototyping and development. Things tend to cost as much as 100 times more than originally anticipated.

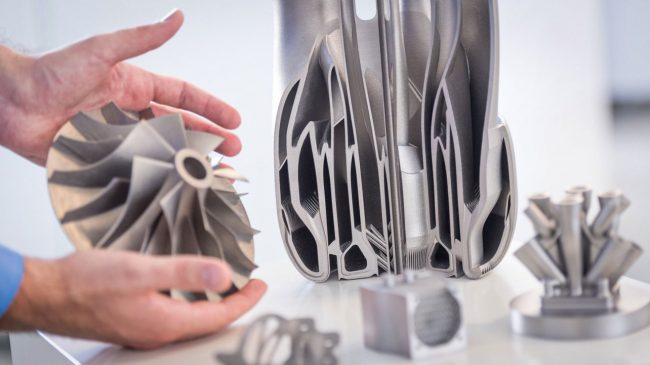

What is low-volume manufacturing?

Low volume manufacturing (LVM) is any manufacturing activity that requires low volumes of finished goods, which can be accomplished relatively easily. In the context of manufacturing, low volume refers to the low volume of products produced. Low volume manufacturing in singapore generally refers to manufacturing undertaken at relatively low operating cost, using relatively simple equipment.

The term “low volume” manufacturing is used in contrast to high volume manufacturing, which uses large machinery to produce large amounts of product. Low volume manufacturing generally involves smaller batches, with shorter runs and turnaround, thus less investment in inventory.

LVM is used for simple products, as well as complex products. LVM is often used for products where the cost of producing small batches is relatively low, such as when low volume production is performed on a one-off basis. LVM also refers to manufacturing activity that is carried out in small quantities, as in small-scale manufacturing. Low volume manufacturing has also been used as a synonym for “cottage industry.”

Low volume manufacturing is often contrasted with high volume manufacturing. Low volume manufacturing is often undertaken in small-scale facilities, using relatively simple machinery.

Low volume manufacturing is often considered to be less intensive than high volume. While high volume manufacturing requires large machinery, low volume manufacturing requires smaller machinery. LYM is used to make products where the cost of producing small batches is relatively low. In the case of low-volume manufacturing, cycle times, or the amount of time it takes to produce the product, are shorter.

Plan for success and project out volumes

To make a product, one needs three things. One needs an idea, money, and people to do the things one cannot do.Ideas are easy to make; it’s much harder to develop a good idea for a product. But ideas are not the hard part. Ideas are easy to patent and easy to copy. Ideas are easy to make and impossible to copy. Money is even easier to get and harder to copy. All one needs is an idea for a product that one can sell.

But people make it hard. It’s easier to get money just by asking for it. And it’s even harder to get money when one asks for it as though one had something to show for their efforts. Bringing people into the picture is even harder. There are thousands of engineers and only a couple of hundred who can build a consumer product. And every one of those engineers has a dozen friends and knows a dozen more. So it is hard to get any work done.The more people who can help, the bigger the potential payoff for an idea. But the bigger the potential payoff, the more one has to convince. And the more convincing one has to do, the more people one has to convince.